When I talk to a grower about adding a meter to their irrigation well, too often the reaction is negative because they fear government monitoring and a tax on their water pumpage. In some states, however, farmers are already paying for the groundwater they pump as measured by water meters. Due to sustained drought conditions in some areas, it is likely that more states will impose metering and reporting of groundwater pumping. Even if taxation of water production is not in play, the metering of water wells has advantages for all well owners.

Based on my experience, I believe that metering your irrigation well is a necessary first step to proper management of resources and overall operating costs. Total water pumpage from wells should always be monitored, as should static and pumping water levels along with energy consumption as an optimum management practice. Every irrigation well owner or well field manager should know their monthly operating cost per well measured in gallons pumped per kilowatt hours of energy used.

Metering and monitoring provide proper management of a single well, a couple of wells or an entire well field. Proper monitoring of well efficiencies will save a farmer money in the long run. Declines in equipment or aquifer performance can be detected sooner than just pumping a well until production declines significantly or the pumping equipment fails completely. Therefore, all large water users should insist on having properly working water meters on their wells. As a former water well contractor, I can attest to the ever-rising cost of replacing pumping equipment and water wells especially during peak growing seasons.

Far too many irrigation water wells are not equipped with flow meters to indicate the flow rate and record total gallons pumped. Most are also not equipped with sounding tubes to measure static and pumping water levels. However, most of them are equipped with a recording power meter because they must pay for the energy used to operate them. Today’s trend in agriculture is to remotely monitor water application, soil moisture plant health and numerous other parameters, so why are growers and farmers reluctant to efficiently manage their water wells? Operating, maintenance and future well rehabilitation costs can be managed just as efficiently as other aspects of farming.

There are two common ratio analysis methods that can be used to monitor and manage irrigation water wells. The first and easiest ratio to monitor is the gallons per minute divided by the drawdown in feet as measured after the well has been pumping for a fixed period of time. This dimensionless ratio is commonly called the specific capacity of the well. If a well was producing 20 gpm per foot of drawdown when it was new, that was an efficient water well. If the same well today is pumping only 10 gpm per foot of drawdown, then the well or the pumping equipment might need attention. The point is that without knowing what that number is, the well owner has no idea what’s going on in the well.

The second and more important ratio is the gallons of water pumped per kilowatt hours of electrical energy used. It is known to well managers as the water-to-wire efficiency ratio, or W/We. This ratio should be measured and monitored no less than monthly to better manage a farmer’s most valuable asset, their water well. While the specific capacity can be used as a general rating of the efficiency of one pumping water well to another, the W/We ratio is an actual value for a specific well. Well field managers often use this ratio to select which well to pump first or longer and which well to use only when needed.

From the time a new irrigation well has been properly constructed, fully developed and pump tested, the owner should know the most efficient pumping rate for that well. This information is then used to properly size the permanent pump for the aquifer and that well. From that date on, the maximum efficiency of the well will slowly decline due to declining water tables or aquifer head, microbial buildup in the openings of the well and on the pump inlet, mineral scale formation, and the wearing of pump impellers.

Slow declines in water production and well efficiency cannot be observed, especially where discharge piping begins at the pump base and goes directly out to the fields. From the start, the most productive aquifer zones provide the highest percentage of the initial flow rate. Microbial fouling and mineral plugging as the well is pumped will impact the most productive zones first. As the better zones begin to foul, other lesser productive zones begin to produce, and the well operator may not see slow declines in productivity. It isn’t until nearly all zones that contribute water flow into the well have become fouled and plugged that a decline in performance is detectable. By that time, the well is already in a state where total well rehabilitation is needed. W/We ratio monitoring would have detected this slow loss of performance had it been monitored. Every time an existing well is rehabilitated, there will be a slightly lower set point of W/We efficiency to begin remonitoring.

Well performance losses can develop so slowly that many farmers will not see the loss until it’s too late. Spending a couple hundred thousand dollars for an irrigation well and not spending just a little bit more for a water meter and a sounding tube does not calculate. It’s only through a coordinated program of collecting readings from water meters and measurements of water levels and tracking that the subtle losses in performance can be detected. If a decline in well efficiency can be seen in real time, a farmer can decide when to rehabilitate the well and/or to replace a pump.

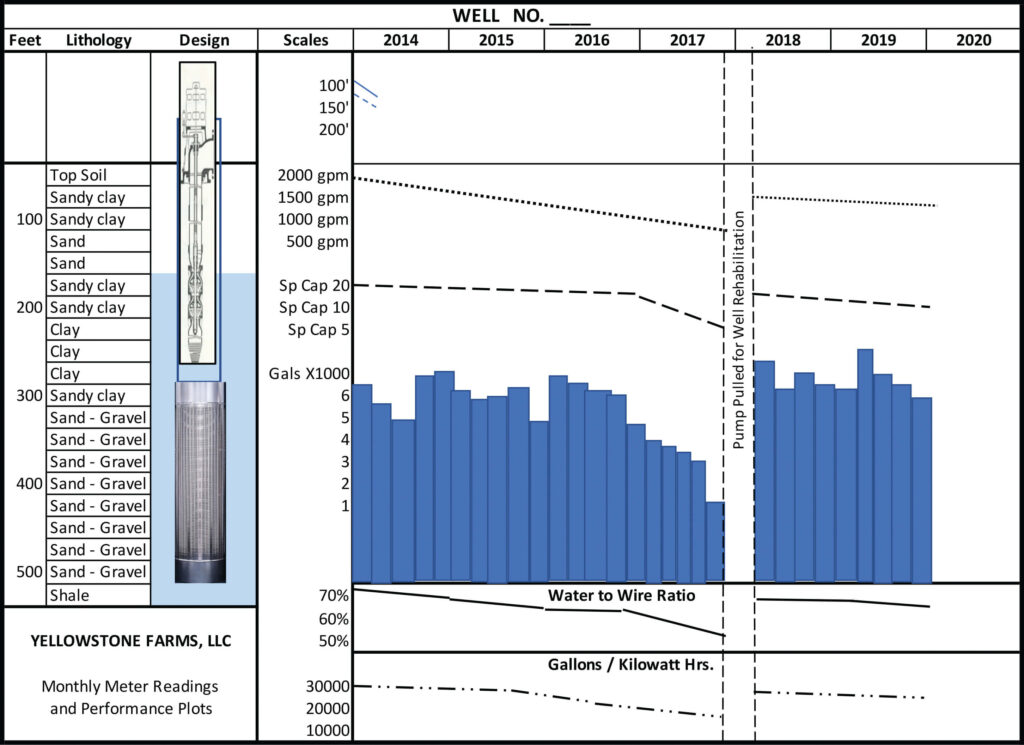

Figure 1 is a composite display intended to illustrate the type of information that a well owner should be keeping for each well they manage. On the left is a Lithology log of the drill cuttings during drilling with depth and a general description of the aquifer with static water levels indicated by a light blue color. The second column is a visual record of the well design and pumping equipment installed.

The third column contains scales for four important measurements taken periodically over the past six years. In late 2017 the pumping water level dropped significantly, the gpm fell off steadily as the specific capacity fell below 10 gpm/feet drawdown and the W/We efficiency approached 50%. At this point it would become clear to the farmer that it was time to pull the pump and rehabilitate the well. Doing a scheduled well rehabilitation or pump replacement in the offseason is preferable to performing one at a critical time in the growing season.

Maximizing the operating efficiency of pumping groundwater to grow crops or produce can save a farmer hundreds of dollars in operating costs yearly. Metering and monitoring an irrigation well can prevent costly failures of the pumping equipment, permanent damage to the well and perhaps even save a crop. The concept of metering irrigation wells for proper management should override the fear of oversight and taxation. That fear should be addressed through collective input to legislators through well owner associations.

In today’s high-tech world of irrigation technology with remote sensing and reporting of crop and soil conditions and water needs, remote performance of water well efficiencies should be incorporated into existing irrigation software programs. There are many large-scale farms supported by irrigation wells where well field management becomes a concern sooner than a small farmer with a single well. Monitoring the performance of all irrigation wells would allow bigger farm managers to stagger routine well maintenance operations.

Will the world of irrigation management see the benefits of this water well management concept as many municipal water providers do routinely? Total control and management of irrigation and crop production should include metering, monitoring and management of water well performance because it is so closely tied to the success of farming operations. The benefits of adding a flow meter and a sounding tube to an irrigation well and collecting and recording readings (if only manually) will pay for itself with reduced well maintenance costs and potential crop damage. Meter, monitor and manage for more efficient operation of your irrigation well or wells.

8280 Willow Oaks Corporate Drive | Suite 630 | Fairfax, VA 22031

Tel: 703.536.7080 | Fax: 703.536.7019

HOME | ABOUT US | ADVERTISE | SUBSCRIBE | CONTACT | PRIVACY POLICY | IA ANTITRUST STATEMENT