Sensor-driven irrigation scheduling has potential for using automated watering to conserve water, energy and labor while achieving grower goals for grape yields and quality. Results from recent research carried out in collaboration with cooperating growers and their funding organizations show promise for growers to use irrigation technologies to remain competitive and sustainable during challenging times for grape and wine-based commodities.

Reliance on having sufficient available water for the duration of the crop production season has become increasingly risky owing to changing climatic extremes, competing demands during drought cycles, and associated costs for obtaining water and applying it in a timely and efficient manner to satisfy crop demands.

While sensors have been used to assess soil water content and crop water stress for decades, most determinations have required manpower in the field to take spot measurements or estimate crop water use from sites some distance from the grower’s field. Even when recording sensors have been placed in a vineyard block, questions remain about the best placement near sentinel plants and proximal distances and depths in soil from the irrigation application points.

Based on results from two research sites in Washington State University near Benton City and Walla Walla, soil water content and soil water tension sensors provided the most consistent results when placed near the base of the vine. This placement location has also proven best for installation of tubular subsurface delivery devices owing to protection from mechanical weed control implements and practices.

Use of buried lines for subsurface microirrigation cannot be practiced in much of the Columbia Basin due to chewing damage by burrowing rodents. To overcome this problem, vertical PVC tubes have been used to deliver drip irrigation that is released about two feet below ground. Water movement within a loamy fine sand has been observed to move via soil capillary action in all directions from the point of water release.

Commercial soil water content probes are available and contain arrays of sensors at fixed points along the depth of the probe. These probes allow installation with minimal disturbance to the soil profile and allow changes in soil water content to be monitored in order to adjust irrigation scheduling. Figure 1 illustrates a typical graphical depiction of soil water content changes in a vineyard being irrigated every four days. Timing of the peak amounts by depth indicate the rate of infiltration or water spread by capillary and root water movement among the depths being measured. Actual soil water content is independent for each depth being measured, but percentages of water content are recorded for each depth and can be observed by use of a moveable curser. Overall water content is shown in the darkened portion at the bottom of the chart.

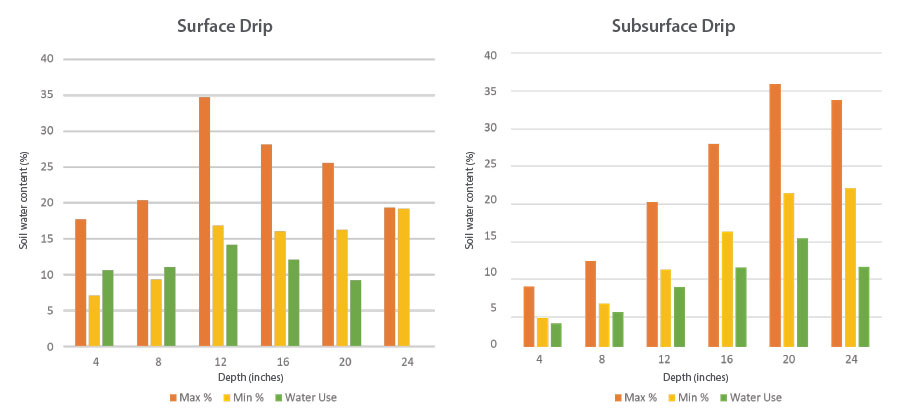

Figure 2 uses a bar graph to visualize soil water content at a vineyard near Benton City at the end of an irrigation event when water content is highest (orange) and just before the next irrigation event when soil water content is lowest (yellow), with the green bar representing the difference or amount of depletion or water use over the four-day period. The left-hand graphs show surface drip and the right-hand set are for subsurface drip with an equal amount of water being applied to both surface and subsurface at each site.

Programmatic algorithms can be used to activate and deactivate irrigation via a designated sentinel sensor. In this data set, the designated sensor was chosen at the 20-inch depth under surface drip application since most of this vineyard block was being managed under surface drip irrigation. The subsurface application was being monitored as a treatment comparison for vine activity and fruit yield and quality. The sensor activates an electronic solenoid valve, and the system allows the length of irrigation to be set by the owner or activated by the sensor when soil water content reaches a designated level.

Another type of sensor is being used at each vineyard site to monitor soil water tension which determines how much of the water content is accessible by the vine. Arrays of these sensors (tensiometers) were placed near the water content sensor probes at depths of 12, 18 and 24 inches within plots watered by surface drip or subsurface drip microirrigation delivery. Data from these sensors are displayed in figure 3. The darkened line at the bottom of these charts indicates the overall soil water tension being measured over time.

While the vine itself is the best indicator of water stress, soil water tension is an early detector of that stress. By the time the vine water stress becomes evident, the vine may have already activated physiological measures or hormonal signals that may not be quickly reversed by adding more soil water. Studies are underway to evaluate the timelines involved and the impact of soil types on these processes in each vineyard.

A moderate level of soil water stress has been cited as beneficial for the enhancement of certain grape components for improving overall quality in winegrapes that lead to production of premium wines with higher retail value. Under an irrigation scheduling regime that replenishes water lost to evapotranspiration at a near equal rate, vines may experience only a brief period of water stress. Winegrape growers generally employ deficit irrigation in which only 70%-80% of water loss is replaced by each irrigation event. Deficit irrigation normally begins after fruit set and ends before harvest.

A hypothesis being evaluated in the studies described in this article will seek to use sensor-driven irrigation scheduling to extend the length of time between irrigation events for the purpose of increasing water stress on the vine for enhancing fruit quality. These studies will add an additional sensor to monitor internal stem water stress within the trunk of the vine.

Algorithms developed from data generated by these three types of sensors collecting real-time data will help develop models that can be used to adjust use of sensor-driven irrigation scheduling to site-specific climatic and edaphic (soil) conditions in the future. These findings may lead to the use of artificial intelligence in vineyard irrigation in the very near future.

8280 Willow Oaks Corporate Drive | Suite 630 | Fairfax, VA 22031

Tel: 703.536.7080 | Fax: 703.536.7019

HOME | ABOUT US | ADVERTISE | SUBSCRIBE | CONTACT | PRIVACY POLICY | IA ANTITRUST STATEMENT